Classical proportions, the sporty yet elegant lines of the BMW 6-Series and the familiar design language of BMW M Automobiles form the foundations for the eloquent body design of the BMW M6 Coupe and BMW M6 Convertible. Powerfully taut surfaces and precise contours underline the athletic aura of the two models. In addition, a model-specific interpretation of hallmark M styling cues includes design details which are influenced directly by technical considerations - such as the cooling air required, chassis geometry and aerodynamics - and therefore further highlight the cars' outstanding performance attributes. This is a fine example of how the ultra-dynamic character which marks out these sportiest versions of the luxurious Coupe and exclusive Convertible is authentically expressed through their design.

Front view: large air intakes, newly designed M kidney grille.

Wide air intakes, stunningly contoured headlight units and large, smooth surfaces shape the front end of the new BMW M6 Coupe and the new BMW M6 Convertible. Another eye-catching element of the car's nose is its newly designed M kidney grille, which bears an "M6" badge. The grille's black, paired kidney grille slats take their cues from the characteristic double-spoke design of the M light-alloy wheels. The 30-millimetre increase in track width over the two cars' respective 6-Series stablemates is complemented by powerfully flared front wheel arches, which sit flush with the wheels. This extra width offers a clear nod to the optimised roadholding of these high-performance sports cars. The three-dimensional shaping of their air intakes and race-inspired flaps designed to optimise airflow to the outer air intakes likewise underline the cars' forward-surging, dynamic character.

An LED accent light cuts across the tops of the Adaptive LED Headlights fitted as standard on both models. Their bright white, three-dimensional LED light rings are levelled off to striking effect at the top and lower edges. Dipped beam and main beam use both light rings. Providing the light are LED units, which are placed on a horizontal rib running through the centre of the units and feed their light into the reflectors in front of them. This ensures that the distinctive appearance of the twin circular headlights comes across clearly in every situation. The direction indicators - in the form of horizontally arranged LED units - are integrated into the headlight units below the light rings.

Side view: athletically flared wheel arches, side gills, forged M light-alloy wheels.

The familiar M athleticism of both models is also clearly visible from the side. The front side sections of the car feature familiar M gills. Their threedimensional shaping, wide chrome frames and indicator bars - which also bear the M logo - give them an extremely deep-set look. In tune with the wider wheel arches, the character lines around the gills are suitably prominent. Eye-catching creases on the likewise model-specific side skirts sweep upwards, diverting the gaze to the rear wheels.

The new BMW M6 Coupe and the new BMW M6 Convertible are fitted with 19-inch M light-alloy wheels as standard. The forged wheels feature seven double-spokes in a two-tone finish. The optional 20-inch M light-alloy wheels, meanwhile, hint at reduced weight with their five intricate double spokes and allow a clear line of sight through to the powerful braking system.

Powerfully shaped rear, typical M twin exhaust tailpipes.

Broadening towards the road and incorporating horizontal lines and generous surfaces, the design of the rear end hints at the stable roadholding and powerful poise and assurance of the new BMW M6 Coupe and new BMW M6 Convertible. The reflectors, positioned immediately below the L-shaped rear lights, provide an individual expression of sportiness.

The clearest pointer to the unmistakable identity of the two high-performance sports cars are the familiar M twin exhaust tailpipes positioned to either side of the diffuser integrated into the rear apron. The outer air intakes reflect the design of the front apron in their format and the contours of their surrounds.

CFRP roof and soft-top in unmistakable design.

Like its predecessor, the roof of the new BMW M6 Coupe is made from carbon fibre-reinforced plastic as standard. The dark colouring of the roof gives the two-door car's silhouette an extremely elongated look, which is further emphasised by a dynamic recess in the centre of the roof. The use of the lightweight material for the roof allows the car's centre of gravity to be lowered, enhancing agility. BMW Individual High-gloss Shadow Line trim (standard) draws attention to this optimised weight balance, its dark colouring covering the side window borders (or the waistline in the case of the BMW M6 Convertible) and the base and lower section of the aerodynamically optimised M exterior mirror caps.

The exclusive looks of the new BMW 6-Series Convertible are underlined by the "fin" architecture of the high-quality soft-top roof. Projecting into the rear section, the fins accentuate the car's dynamically sweeping silhouette. The heated, vertical glass rear window, which is situated just behind the rear seats, retracts independently of the soft-top itself.

Customers can choose from one non-metallic and eight metallic shades (including four exclusive M finishes) for the exterior paintwork of both models. The soft-top for the new BMW M6 Convertible is available in Black and Beige, or - as an option - in Anthracite Silver effect.

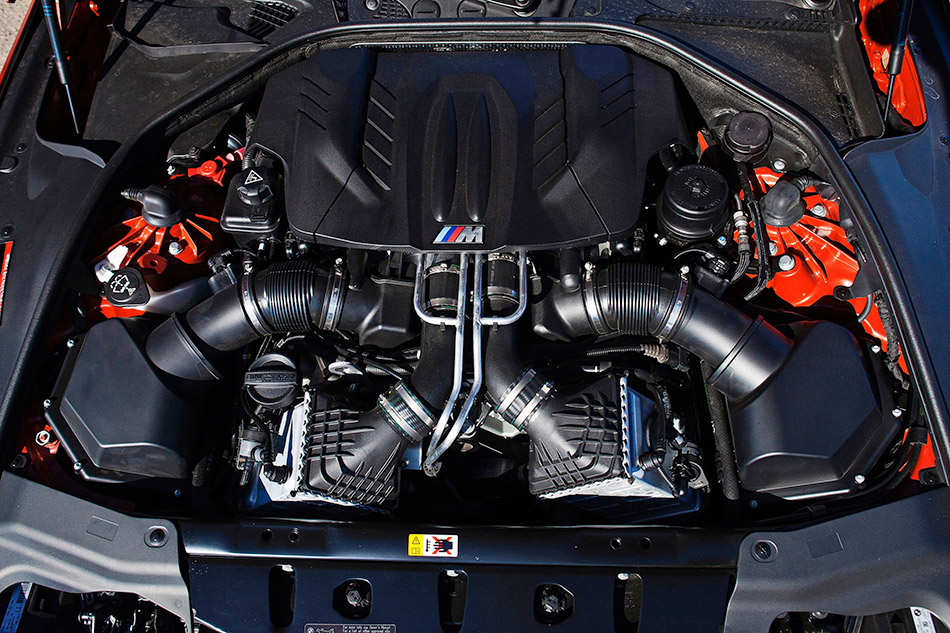

Drivetrain: Power and character.

The new BMW M6 Coupe and new BMW M6 Convertible showcase their individual style with a raft of unique styling touches and tweaks to the character of the driving experience. But they draw the output required to serve up their inspirational performance from the same source: a high-revving V8 engine with M TwinPower Turbo technology, longitudinally mounted at the front of the car, whose power is channelled to the rear wheels via a sevenspeed M Double Clutch Transmission with Drivelogic.

This powertrain combines construction features taken directly from motor sport with innovations developed under the banner of Efficient Dynamics. Its globally unparalleled package of technology comprises two turbochargers working according to the twin-scroll principle (including a cross-bank exhaust manifold), High Precision Direct Petrol Injection, VALVETRONIC variable valve timing and Double-Vanos continuously variable camshaft control. The engine is also served by an extremely powerful cooling system and a wet sump oil supply optimised to work under high lateral forces.

Output increased by 10 per cent, peak torque boosted by 30 per cent, fuel consumption and emissions cut by more than 30 per cent.

The unmistakable, typically M performance characteristics of the 4.4-litre powerplant are defined by its lightning-quick responses and forceful, linear power delivery maintained into the higher reaches of the rev range. Indeed, peak torque of 680 Newton metres (502 lb-ft) is on tap between 1,500 and 5,750 rpm. The V8 achieves its maximum output of 412 kW/560 hp between 6,000 and 7,000 rpm and can spin on to 7,200 rpm. All of which means the rev band available in the new models to generate maximum performance is almost three times wider than that of the engine powering their predecessors.

This instantaneous and sustained power delivery is the key to unlocking the cars' intoxicating acceleration. The new BMW M6 Coupe dashes from rest to 100 km/h (62 mph) in 4.2 seconds, while the new BMW M6 Convertible reaches the same speed just 0.1 seconds later. The top speed of both models is electronically limited to 250 km/h (155 mph). Specifying the optional M Driver's Package raises this barrier to 305 km/h (189 mph).

The advances in engine development enshrined in M TwinPower Turbo technology are also reflected in the two new models' significantly greater efficiency compared to their predecessors. The high operating effectiveness of the engine, the standard-fitted Auto Start-Stop function and other examples of Efficient Dynamics technology, such as Brake Energy Regeneration and the volume-controlled oil pump, help to reduce fuel consumption and emissions by some 30 per cent. The new BMW M6 Coupe cards average fuel consumption of 9.9 litres per 100 kilometres (28.5 mpg imp) in the EU test cycle and CO2 emissions of 232 grams per kilometre. The corresponding values for the new BMW M6 Convertible are 10.3 litres per 100 kilometres (27.4 mpg imp) and 239 grams per kilometre.

Harnessing the high output to dynamic effect: the seven-speed M Double Clutch Transmission with Drivelogic.

Tuned seamlessly to the performance characteristics of the V8 engine, the M Double Clutch Transmission with Drivelogic converts the powerplant's impressive thrust extremely effectively into rapid acceleration. This capability is underpinned by the DCT design principle, which effectively combines two gearboxes in one housing - yet with virtually no size or weight penalty over a conventional manual transmission. Inside the transmission, the torque is transferred via two oil-cooled wet clutches, which are engaged alternately. This allows zero interruption in the flow of power when the driver accelerates, even during gear changes.

M DCT Drivelogic offers the driver three different shift programs, both in automated mode (D) and in manual mode (S). These programs alter the transmission's shift characteristics in terms of efficiency, shift comfort and sportiness and can be activated using the rocker switch located behind the selector lever on the centre console. Added to which, the electronics also provide a Launch Control function ensuring unbeatable acceleration from a standing start, Low Speed Assistance for easier low-speed operation, and the Auto Start-Stop function for increased efficiency.

The special M gear selector is used for selecting D and S modes and for engaging reverse gear. In S mode the driver changes gears manually in a sequential format. The new BMW M6 Coupe and Convertible are also equipped as standard with a newly developed M leather steering wheel, complete with multifunction buttons and fixed gearshift paddles. In typical M configuration, the driver pulls the right-hand paddle to shift up and the lefthand paddle to shift down.

Chassis: Supreme precision in any situation.

The motor sport technology in the new BMW M6 Coupe and new BMW M6 Convertible paves the way for imposing performance on the race track, but also treats the driver to a captivating driving experience on everyday journeys from A to B. The dynamic character of both models is defined not only by their acceleration from standstill but also by their mid-range agility, the precision of their turn-in and traction when accelerating out of corners, their precisely controllable handling under intense lateral forces and their stopping capability. Paving the way for this is the model-specific chassis technology in conjunction with the Active M Differential, an ideal weight balance and optimised aerodynamic properties.

The precise interplay of the powertrain, chassis and body has been honed in detail as part of extensive testing on the NürburgringNordschleife. The upshot is an unmistakable M feeling of a particularly intense kind. As the latest innovation to optimise handling in ultra-dynamic driving situations, the optional M carbon-ceramic brake system marks its debut in the new BMW M6 Coupe and new BMW M6 Convertible.

M-specific chassis technology, Dynamic Damper Control, M Servotronic, DSC with M Dynamic Mode.

The chassis of the new BMW M6 Coupe and new BMW M6 Convertible has been developed to M specification and therefore combines outstanding performance attributes with the comfort-enhancing features drivers appreciate on an everyday basis. Like the integral rear axle, whose subframes are bolted rigidly to the body, the double-wishbone front axle boasts specific kinematics and newly developed components made from forged aluminium. Chassis mountings using large panels at the front and rear axle ensure dynamic forces are passed evenly through to the body, making for highly precise wheel control.

The standard equipment of both models also includes electronically controlled dampers. The M-specific Dynamic Damper Control system adjusts damping force electrohydraulically to provide the required responses for the driving situation at hand and fulfil the wishes of the driver. A choice of three settings allows drivers to adjust the damper characteristics to their needs and preferences.

The hydraulic rack-and-pinion steering ensures unbeatable precision and a high degree of comfort. This system has a variable ratio, which enhances straightline stability and reduces the number of steering wheel turns required when parking and turning off a road. The likewise standard Servotronic speedsensitive power assistance is specially tuned to M specification and allows drivers to choose a personal configuration with the help of three set-up options.

In addition to applying brake impulses and reducing engine output to stabilise the car, the DSC stability control system of the two high-performance sports cars also employs the services of the Anti-lock Braking System (ABS), Cornering Brake Control (CBC) and Dynamic Brake Control (DBC), along with a Brake Assistant, the Brake Drying function and Start-Off Assistant. M Dynamic Mode (MDM) can be activated to override the basic setting by pressing the DSC button. By raising the intervention thresholds of DSC, this mode makes it easier to move off on snow or loose sand with slightly spinning driven wheels. MDM mode also paves the way for the familiar M self-steering response. "DSC Off" mode can likewise be activated at the touch of a button.

Active M Differential delivers outstanding traction in dynamic driving situations.

The new BMW M6 Coupe and new BMW M6 Convertible also impress by offering optimum traction in tricky road and weather conditions and under dynamic acceleration out of corners. Working behind the scenes to this end is an innovative variable locking differential in the rear differential. The Active M Differential allows the engine's power to be split precisely and quickly between the left and right rear wheel according to the requirements of the driving situation at any particular moment.

An electronically controlled multi-plate limited-slip differential helps to reduce the rotational speed differences between the rear wheels, which is needed to optimise traction. The Active M Differential control unit is linked up to the DSC stability control system, allowing every driving situation to be precisely analysed and a loss of traction at one wheel to be detected at an early stage. The locking effect generated in response can be varied between 0 and 100 per cent, enabling wheel spin to be prevented on slippery surfaces, in instances where the left and right rear wheel have widely differing friction coefficients, in tight bends and when changing direction extremely dynamically.

An innovation for precise handling: M carbon-ceramic brakes.

The latest version of the compound high-performance braking system helps give the new BMW M6 Coupe and new BMW M6 Convertible outstanding stopping power. Its stand-out features include even lower weight, excellent feel and fade-free performance even under heavy loads. The diameter of the inner-vented and perforated brake discs is 400 millimetres at the front and 396 millimetres at the rear. The six-piston fixed-calliper brakes at the front axle - painted dark blue metallic and complete with the M logo - are radially bolted to the pivot bearing.

The M carbon-ceramic brakes available for the first time for the new BMW M6 Coupe and new BMW M6 Convertible (in conjunction with 20-inch M light-alloy wheels) take the cars' stopping power to another new level. The brake discs measure 410 millimetres in diameter at the front axle and 396 millimetres at the rear. Made from a new type of carbon-fibre compound ceramic, the discs boast even greater resistance to heat and combine this with significantly reduced rotating masses. The M carbon-ceramic brakes are 19.4 kg lighter than the standard-fitted items, yet the innovative material also displays exceptional resistance to wear, and the operating life of the discs is many times that of conventional equivalents. The optional M carbon-ceramic system also sees six-piston fixed-calliper brakes at the front teaming up with single-piston floating-calliper brakes at the rear. The callipers can be identified by their special gold-coloured paint finish.

Body, CFRP roof, soft-top: Robust, lightweight, expressive.

An intelligent blend of materials also gives the body structure impressive strength coupled with extremely low weight, allowing it to enhance both occupant protection and handling agility. As with the use of CFRP for the roof of the new BMW M6 Coupe, the choice of materials for all other body components slots into the all-round lightweight design strategy. The doors and bonnet of the two high-performance sports cars are made from aluminium, the front side panels from thermoplastic. In addition, their boot lids and - in the case of the BMW M6 Convertible - also the roof cover are made from the glass-fibre composite material SMC (Sheet Moulding Compound). A weight-to-power ratio of 3.3 kg/hp for the new BMW M6 Coupe and 3.5 kg/hp for the new BMW M6 Convertible points to the significant advances that have also been made in this area over the predecessor models.

Robust load-path structures, large and precisely defined deformation zones and highly efficient restraint systems provide the basis for a high level of passive safety in both models. The safety equipment fitted as standard includes front and side airbags, side curtain head airbags for both rows of seats in the new BMW M6 Coupe, and front airbags and head-thorax side airbags integrated into the seat frames of the new BMW M6 Convertible. The soft-top model also benefits from roll-over bars made from high-strength aluminium. Positioned behind the rear head restraints, these protective bars extend automatically in fractions of a second should there be a danger of the car rolling over. Both models come with three-point inertia-reel seat belts on all seats, belt force limiters and belt tensioners for the front seats and ISOFIX child seat attachments in the rear.

Both the new BMW M6 Coupe and new BMW M6 Convertible are designed as four-seaters, and space in the rear compartment has increased substantially compared with the predecessor models. The load capacity of the new BMW M6 Coupe stands at 460 litres. The new BMW M6 Convertible, meanwhile, can carry 300 litres of luggage in the boot with the soft-top down and 350 litres with it closed. Both models can be ordered with the optional ski bag, which slides between the rear seats courtesy of the through-loading facility.

Dynamic contours, lightweight material: the carbon fibre-reinforced plastic roof of the BMW M6 Coupe.

Like its predecessor, the roof of the new BMW M6 Coupe is made from carbon fibre-reinforced plastic as standard. The dark colouring of the roof gives the two-door car's silhouette an extremely elongated look, which is further emphasised by a dynamic recess in the centre of the roof.

The use of the lightweight material for the roof allows the car's centre of gravity to be lowered, thereby enhancing agility. BMW Individual High-gloss Shadow Line trim (standard) draws attention to this optimised weight balance, its dark colouring covering the side window borders (or the waistline in the case of the BMW M6 Convertible) and the base and lower section of the aerodynamically optimised M exterior mirror caps.

BMW M6 Convertible: high-quality soft-top with characteristic "fin" styling and automatic opening and closing function.

The exclusive looks of the new BMW 6-Series Convertible are underlined by the "fin" architecture of the high-quality soft-top roof. Projecting into the rear section, the fins accentuate the car's dynamically sweeping silhouette. The heated, vertical glass rear window, which is situated just behind the rear seats, retracts independently of the soft-top itself. The automatic opening and closing process for the roof can be activated both at a standstill and while on the move at speeds of up to 40 km/h (25 mph) using a button on the centre console. The optional Comfort Access allows the roof to be opened or closed by pressing the remote control button on the car key. It takes the roof 19 seconds to open and 24 seconds to close again.

Interior and operating concept: Pure M feeling, sheer luxury.

The luxurious interior ambience of the new BMW M6 Coupe and the new BMW M6 Convertible is characterised by classy materials and dynamically moulded surfaces, and the bespoke design of the cockpit and centre console - cleverly drawing on the exclusive, high-performance sports car driving experience - lends it an extra individual flair. The instrument cluster with black-panel technology features classical circular instruments in traditional BMW M style, with red needles and white illumination, as well as model-specific displays and the M logo in the rev counter.

The standard-fitted iDrive control system includes a Controller on the centre console, direct menu control buttons and functional bookmarks, as well as an onboard monitor with an exclusive flatscreen design. The optional Navigation system Professional brings with it a 10.2-inch version of the Control Display bordered by a high-quality, galvanised chrome frame.

M leather steering wheel and M sports seats in new, model-specific design.

The model-specific M leather steering wheel of the new BMW M6 Coupe and new BMW M6 Convertible are distinguished by their smaller rim diameter and a new design which takes its cue from the double-spoke construction of the M light-alloy wheels. The likewise newly developed M sports seats offer the driver and front passenger optimum lateral support through quickly-taken corners, but also a high level of comfort over long distances. The lightweight seats with integrated belt system have an M-specific design headlined by extremely prominent cushion and backrest bolsters, head restraints integrated into the backrests, eye-catching stitching emphasising the segments of the seats, and an M logo embossed into the shoulder area.

The M sports seats have electric height, fore/aft and backrest angle adjustment, and also come with pneumatically adjustable lumbar support, a memory function and a manually adjustable thigh support. The M sports seats are fitted with active head restraints to reduce the risk of injury in a rear-end impact.

Ideal vehicle set-up at your fingertips: M Drive buttons.

Arranged around the gearshift lever on the model-specific centre console are the buttons allowing drivers to select their preferred settings for all the adjustable powertrain and chassis functions. The DSC mode, performance characteristics of the engine, Dynamic Damper Control mapping, M Servotronic responses and M DCT Drivelogic shift program can all be adjusted independently at the touch of a button. This allows drivers to put together a detailed set-up configuration for their car and store it by holding down one of the two M Drive buttons on the multifunction steering wheel. The two standard-fitted M Drive buttons allow the driver of the new BMW M6 Coupe and new BMW M6 Convertible to store a dynamic-led configuration under the "M1" button, for example, and a comfort-biased set-up under "M2" - and to call up either in an instant and at any time. The settings stored on the M Drive buttons can also be configured using the iDrive menu.

As with the cars' performance characteristics, the aural profile of the engine can also be tweaked at the touch of a button. In parallel with the exhaust flap control, a sound module is used to enhance the engine's natural acoustic components and this soundtrack is then conveyed into the interior. The system's digital signal processing technology exchanges data directly with the engine management and adjusts its output to the engine's revs, the amount of torque being produced and the car's speed over the road. This gives the driver an impressively accurate impression of how hard the engine is currently working and of the power being unleashed, and provides an even clearer window into the car's responses on the road.

Equipment and BMW ConnectedDrive.

The exclusive character of the two high-performance sports cars is underlined by the high-quality and extensive array of standard equipment they have on board - not to mention an unrivalled selection of high-tech options lending further depth to the driving experience. Standard equipment for both models includes 2-zone automatic climate control, heated seats for the driver and front passenger, fine-grain Merino leather trim with extended features, an M driver's footrest, exclusive carbon-fibre interior trim strips, door sill strips with "M6" lettering, plus ambient light in the interior, an automatically dimming rear-view mirror and exterior mirrors (the exterior mirrors also have a folding function), Cruise Control with braking function, an alarm system and the BMW Professional radio with HiFi loudspeakers.

The range of optional driver assistance systems and mobility services available from BMW ConnectedDrive add unique touches to the two new models. The M-specific version of the Head-Up Display - which, alongside a digital speed readout and tips from the optional Speed Limit Info, also shows the gear currently engaged and a multicolour rev counter symbol, complete with Shift Lights - is joined in the line-up by features including Park Distance Control, a rear-view camera, High Beam Assistant, Speed Limit Info, Lane Change Warning and Lane Departure Warning, Surround View and BMW Night Vision with pedestrian recognition. Innovative technologies also optimise the integration of the Apple iPhone and other smartphones, as well as music players, and incorporate the use of internet-based services. The Apps option allows iPhone owners to receive web radio stations, for example, and display Facebook and Twitter posts on the onboard monitor. The Real Time Traffic Information function, meanwhile, keeps the driver supplied with impressively accurate and detailed traffic bulletins.

High-performance audio: Bang & Olufsen High End Surround Sound System.

Additional highlights of the options list include the navigation system Professional with hard disk storage, M multifunction seats with electric backrest width adjustment, active seats, active seat ventilation, Comfort Access, a heated steering wheel, the Soft Close Automatic function for the doors, and the Bang & Olufsen High End Surround Sound System. This audio system brings high performance into the world of in-car sound reproduction.

The fully active system with digital signal processing comes with individual amplifiers for all the bass speakers, mid-range speakers and tweeters. Its centre speaker uses the Acoustic Lens Technology developed by Bang & Olufsen. As soon as the audio system is activated, the central element containing the integrated mid-range speaker pops up from the instrument panel, prompting the tweeter lens to extend out at the same time. The total of 12 loudspeakers in the new BMW M6 Convertible and 16 loudspeakers in the new BMW M6 Coupe deliver a uniquely rich and dynamic sound experience.

Model history: Tradition firmly rooted in motor sport.

Considering the BMW 6-Series has motor sport ingrained in its DNA, it comes as little surprise that the origins of the BMW M6 model lie in the early 1970s. When BMW Motorsport GmbH was founded in May 1972, it was immediately tasked with the development of a racing car built on the basis of the BMW 3.0 CS luxury coupe to compete in touring car races. Powered by a 3,340 cc six-cylinder in-line unit initially generating 360 hp, the BMW 3.0 CSL - the L in its name stood for lightweight design - established itself as the most successful touring car of its day, at the same time as showcasing innovations whose technical details filtered through to production car development. Aluminium doors, bonnet and boot lid as well as a five-speed gearbox with magnesium casing were followed in 1973 by the first ever six-cylinder engine with four-valve technology, and then, in 1974, by the debut of the anti-lock braking system. It was firsts such as these that helped to speed the car to success on the race track before finding their way into the brand's roadgoing models - and this same principle continues to be a defining characteristic of BMW M cars today.

The BMW 3.0 CSL won a total of six European Touring Car Championship titles between 1973 and 1979, with power output increasing year on year. By 1976 it already had a 3.2-litre six-cylinder biturbo engine under the bonnet, whose output actually had to be throttled to 750 hp. In the meantime, a brand-new project was taking shape at BMW Motorsport GmbH: a mid-engined supercar developed completely from scratch. Before the BMW M1 could line up for the new Procar Championship, however, 400 units had to be built for homologation purposes. This was how BMW Motorsport GmbH came to bring out its first production car in 1978: not only did the BMW M1 with its 277 hp straight-six engine instantly acquire the title of Germany's quickest production sports car, the entire run of 456 models was snapped up by customers with lightning speed too.

Motor sport technology for the road: the BMW M635i.

By now, the BMW 3.0 CS had been replaced by the BMW 6-Series in the BMW model line-up. And the appetite of many BMW drivers for extra power in their standard production cars had not gone unnoticed by BMW Motorsport GmbH: the free-revving four-valves-per-cylinder engine from the BMW M1 was the perfect choice for evolving the BMW 6-Series luxury coupe into the mighty BMW M635i. The six-cylinder unit unleashed 286 horsepower which, allied to chassis technology that had been precision-honed to handle it as well as streamlined body components, allowed drivers to enjoy a real taste of motor sport during their day-to-day driving. A total of 5,855 BMW M635i models were sold between 1984 and 1989.

The dawn of a new era of phenomenal performance and high tech galore: the first BMW M6.

In 2005, two years after the second generation of the BMW 6-Series made its debut, BMW M GmbH added a high-performance sports car to its portfolio that was simply in a class of its own. The BMW M6 instantly became the epitome of a highly prestigious breed of top-performance automobile brimming with motor racing know-how. Its performance credentials made stunning reading: a high-revving V10 engine derived straight from Formula One with a 5.0-litre displacement and a power output of 373 kW/507 hp, seven-speed Sequential M Gearbox with Drivelogic and Launch Control for accelerating from stationary at maximum power, speed-sensitive, variable M differential lock, plus model-specific chassis technology including Electronic Damper Control (EDC) and compound brakes. The V10 power unit took the overall prize at the highly prestigious International Engine of the Year Awards for two years running, in 2005 and 2006. And in the two years that followed it came top in the category for engines above 4 litres.

The pioneering and progressive character of the BMW M6 is also due in no small part to its trailblazing driver assistance systems, such as the Head-Up Display with its M-specific readouts. One year after the Coupe went on sale it was followed by the BMW M6 Convertible. By 2010, global sales of the high-performance sports car totalled 14,152 units, with the Coupe accounting for 9,087 of these and the open-top version of the BMW M6 the remaining 5,065.

Production: Innovative processes for exceptional automobiles.

With its state-of-the-art production processes and its years of experience in the manufacture of highly exclusive premium automobiles, BMW's Dingolfing site makes a natural choice for building the new BMW M6. Here, at the biggest BMW plant in the world, the M6 Coupe and the M6 Convertible are built on the same assembly lines as the BMW 6-Series models. The luxury BMW 7-Series Sedan models and the BMW 5-Series models are also built here. All these cars, including the BMW M6, benefit from the sharing of product and process modules between different model series, resulting in further improved production efficiency and manufacturing quality. The integrated manufacture of the high-performance sports cars also includes production and assembly of their model-specific chassis, body and interior components.

The BMW plant in Dingolfing, Lower Bavaria, has been part of the global BMW production network since 1967. Today this network comprises plants in 14 different countries. In 1973, BMW began producing complete vehicles at this site, at the newly constructed Plant 2.4. Numerous awards are proof that this plant, which has built more than 8 million BMW automobiles to date, sets very high standards. Approximately 18,600 people currently work at the site, more than 12,000 of them in vehicle production at Plant 2.4.

V-engine production in Munich: cutting-edge technology meets precision craftsmanship.

Based on a well-established process, the high-performance engine of the new BMW M6 is built in the production shop for special-category engines at the BMW Plant Munich. On the V(flex) production line here at BMW's home plant, the engine is built alongside M3 engines and the 12-cylinder units for the BMW 760i and the latest Rolls-Royce models. High-tech processes and the precision craftsmanship of experienced experts guarantee outstanding quality standards.

The engine block and crankcase of the V8 engine are produced in the light-alloy foundry at the BMW Landshut plant. At the start of assembly at the Munich plant the basic engines are mounted on carriers, each of which is fitted with an integrated data storage device. This allows quality-related data to be retrieved during the assembly process. For example, at automated bolting stations the right assembly programs with the correct tightening torques for bolted connections can be activated. At all subsequent assembly stations, too, the engine-specific data helps ensure that employees use the right tools and apply the correct tightening torques. At the same time, core components such as cylinder heads and connecting rods are also coded. This allows them to be precisely tracked from their arrival at the factory through to final assembly. The manufacturing process concludes with a function test on the test bench which each and every engine has to pass before being sent to BMW Plant Dingolfing.

Integrated production optimises quality and efficiency.

Integrated production based on shared product and process modules allows the Dingolfing plant to optimise manufacturing quality and efficiency - in line with the BMW Value-Added Production System (VPS). Standardised processes allow top-quality multi-model production on a single assembly line to be combined with integrated production planning. Flexible design of the production systems enables the factory to maintain consistently high levels of capacity utilisation, while also ensuring short delivery times within the Customer-Oriented Sales and Production Process (KOVP). Further synergy effects are achieved through use of "product modules" (modular component design).

At the same time, innovative production techniques have been developed which can now be applied across a number of different models and thus across higher production volumes. For example, the door production process is based on research and development work carried out at the BMW Group's Dingolfing-based Aluminium Competence Centre.

Newly developed aluminium processing technology also facilitates intricate modelling of sophisticated design features such as the character line on the doors. For sheet steel components, too, innovative manufacturing processes are used. At the Dingolfing plant, BMW became the world's first carmaker to use hot-stamping technology, whereby galvanised sheet steel is cold-formed, then heated to a temperature of over 900 degrees Celsius, then immediately cooled to a temperature of around 70 degrees and hardened. The cooling is performed in a press with integrated water cooling and takes just a few seconds. This technique gives the components between three and four times the strength of conventional sheet steel.

Pioneering the material of the future: the BMW M6 Coupe's CFRP roof.

One of the most striking features of the new BMW M6 Coupe is its carbon fibre-reinforced plastic (CFRP) roof. BMW has extensive expertise in the manufacture of carbon parts, which first went into volume production at the BMW Landshut plant in 2003. In 2013, this plant will also start manufacturing the CFRP passenger cells for the all-electric BMW i3, and for the BMW i8 plug-in hybrid sports car. Alongside their respective drive technologies, lightweight design based on use of CFRP is a key feature of both vehicles.

The predecessor of the new BMW M6 Coupe was among the first pioneers of carbon-fibre parts - the material of the future. It was the first model whose roof and bumper supports were both mass-produced from CFRP. Since then, production volumes for carbon-fibre parts have been growing steadily. The current BMW M3 is likewise equipped with a CFRP roof. On the new BMW M6 Coupe, further advances in production technology have enabled the designers to give the CFRP roof striking, aerodynamically optimised contouring.

The extremely lightweight, yet at the same time very sturdy material used in the roof combines optimal stiffness with a significant reduction in weight. This lowers the centre of gravity and makes the BMW M6 Coupe even more agile. A CFRP roof brings weight savings of around 50 per cent over steel and 30 per cent over aluminium, for equivalent or improved functional performance. CFRP also offers outstanding crash performance and extreme durability.

Source: BMW